Four Basic Methods For Making A Sculpture Are

Four Basic Methods For Making A Sculpture Are

Four basic methods for making a sculpture are:

- Carving

- Modeling

- Constructing and Assembling

- Welding

The aesthetic effect of certain types of sculptures mostly depends on the way artists directly manipulate their materials. For many sculptors, the actual physical process of the work material is an integral part of the art of sculpture. In the finished work, their response to the work quality of the material (such as its plasticity, hardness and texture) is obvious. Design and craftsmanship are closely integrated in this kind of work, which is a highly personal expression.

Carving

No matter which material is used, the basic characteristics of the direct carving method are the same. The sculptor starts with a solid material and then systematically reduces it to the desired form. First he or she has determined the main objects and planes that define the outer limits of the forms. Then he or she works step by step throughout the sculpture, sculpting the larger containing forms and planes. The forms and planes are sculpting smaller , until the final surface details are formed. Finally the artist finishes the required surface treatment. Even with a preliminary model as a guide, as the work progresses, the concept of the sculptor will continue to evolve and clarify. Therefore, when he or she adjusts the design according to the carving process and the nature of the material, the work develops into an organic whole.

The process of direct carving gives a characteristic sequence to the form of the sculpture. Usually, the surface of the original block, flat plate or cylinder can still be felt. These surfaces exist as an implicit spatial envelope in the finished work, thus limiting the extension of the form in space and connecting its highest points to the entire space. In a similar way, in the entire carving process, smaller shapes and planes can be regarded as being contained in implicitly larger shapes and planes. Therefore, an ordered sequence of containing forms and planes, from the largest to the smallest, gives unity to the work.

Indirect carving

In Western civilization during the 19th and early 20th centuries direct carving became customary for stone. And to a lesser extent, wood sculpture to be produced by the indirect method. This requires the production of the finished clay model, which is then cast in plaster. And then more or less mechanically copied in stone or wood by a pointing machine.

Usually, the carving is not done by the sculptor himself. In the worst case, this process will produce a carved copy of the design conceived from the clay model. Although indirect carving cannot achieve the aesthetic quality of engraved sculptures. It also does not necessarily lead to a decline in carving quality. For example, Rodin’s marble sculptures are generally regarded as great works of art, even by those who oppose indirect carving. Since the revival of direct carving in the early 20th century and the innovation of 3D printing at the end of the century, indirect methods have been steadily losing ground.

Carving tools and techniques

The tools used for carving differ depending on the material being carved. The stone is mainly carved with steel tools similar to cold chiseling. To knock off the corners and angles of the block, use a heavy hammer to drive a tool called a pitcher into the surface. The pitcher is a thick chisel-like tool with wide beveled edges that can break rather than cut stones. Then focus on the main roughing and then the fine points, which can be used within a short distance from the final surface. These pointed tools hammer into the surface at an angle, causing the stone to break into pieces of different sizes.

Claw chisels, which have toothed edges, may then be worked in all directions over the surface, removing the stone in granule form and thus refining the surface forms. Flat chisels are used to complete surface carving and cutting sharp details. There are many other special tools, including stone chisels, drill bits, toothed hammers (called bushhammers or bouchardes), as well as electro-pneumatic tools that are often used today to strike the surface of the stone. The surface can be polished using a variety of processes and materials.

Because most engravers in the Middle Ages used softer stones and used flat chisel extensively, their works often had avant-garde cutting quality and could be carved freely and deeply. In contrast, the work that people do on hard stone lacks metal tools that are hard enough to cut the stone. For example, Egyptian granite sculptures are mainly made by abrasion; that is, by hitting the surface and rubbing it with abrasive materials. The result is a compact sculpture, not deeply hollowed out, with soft edges and a flowing surface. It usually has a high tactile appeal.

Although the carving process of wood or stone is basically the same, the physical structure of wood requires different types of tools. For the first carving of woodcarving, the sculptor may use a saw and axe, but his main tools are various woodcarving chisels. The sharp curved edge of the chisel can easily penetrate the fiber bundle and will not split the wood if used properly. A flat chisel is also used, especially for carving sharp details. A wooden file or rasps and sandpaper can be used to smooth the surface, or, if desired, a faceted, well-defined appearance can be left. The woodcarving tools have hardwood handles and are struck with a round mallet. African woodcarvers use various adzes instead of chisels and mallets. Ivory is carved with various saws, knives, files, files, chisels, drills and scrapers.

Modeling

Contrary to the restoration process of sculpture, modeling is essentially a construction process in which the sculpture grows organically from the inside. Many plastic materials are used for modeling. There are mainly clay, gypsum, and wax; but concrete, synthetic resin, plastic wood, plaster, and even molten metal can also be modeled. A design modeled in plastic materials may be designed to be replicated by casting more durable and rigid materials (such as metal, plaster, concrete, and fiberglass), or it may itself be made rigid and more durable through the self-defined properties of its materials (For example, gypsum) or by firing.

Modeling for casting

The most widely used material for making positive models for casting is clay. Small and compact design or low relief can be firmly modeled in clay without any internal support; but a large clay model must be formed on a strong skeleton made of wood and metal. Since the armature can be very delicate and can only be changed slightly, if any, once the work starts, the modeler must get a fairly clear idea from his drawings and the model of the main shape arrangement of the finished model. The underlying main mass of the sculpture is firmly established on the armature, and then smaller forms, surface modeling and details are modeled on them. The main tool of the stylist is his fingers, but for fine work, he may use various wooden modeling tools to apply clay and wire loop tools to cut them off. The relief is modeled on a vertical or nearly vertical plank. The clay is fixed or fixed to the board with galvanized nails or wooden slats. The number of armatures required depends on the height of the relief and the weight of the clay involved.

In order to make metal castings, the foundry needs a sculptor to make a model made of a rigid material, usually plaster. The sculptor can make by modeling in clay and then casting plaster from the clay model or directly modeling in plaster. For direct plaster modeling, since the material is fragile, a strong skeleton is required. The main form can be roughly constructed with expanded wire on the armature and then covered with a scrim (loosely woven sacks) impregnated with gypsum. This provides a hollow foundation for the final shape, which is done by applying plaster with a metal spatula and scraping and cutting with a file and chisel.

The fiberglass and concrete sculptures were cast in plaster molds taken from the sculptor’s original model. The model is usually clay rather than plaster, because if the form of the sculpture is very complex, it is easier to remove the plaster mold from the soft clay model than from the hard material (such as plaster).

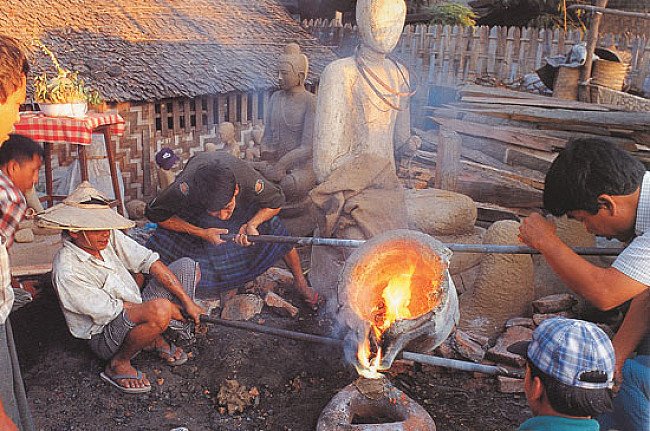

A large number of metal sculptures in the past, including Nigeria, India and many Renaissance bronzes, were produced through a direct lost wax process, which involved a special modeling technique (see casting and molding below). The design is first modeled in some refractory materials to within a fraction of an inch of the final surface, and then the final model is completed in a layer of wax. Using fingers and metal tools, it can be heated to make the wax more flexible. Medals are usually made of wax originals, but due to their small size, they can be cast in solid, so no core is required.

Modeling for pottery sculpture

In order to withstand the pressure of firing, large pottery sculptures must be hollow and uniform in thickness. There are two main ways to achieve this. In the process of hollow modeling, this is the typical modeling method of potters. The main form of the clay model is directly constructed as a hollow shape with approximately uniform wall thickness. The construction method is similar to the method used to make handmade pottery-coiling, kneading and slab. Then add smaller forms and details, and let the finished work dry out slowly and thoroughly before firing. The process of solid modeling is more like the traditional modeling method of sculptors. Sculptures are modeled in solid clay, sometimes on a carefully considered skeleton, through the usual clay modeling methods of the sculptor. Then cut it open and hollow it out, if there is an armature, remove the armature. Then the pieces were reconnected, and the work was dried and fired.

General characteristics of modeled sculpture

The modeling process affects the design of the sculpture in three important ways. First, the form of sculpture tends to be sorted from the inside. There are no external forms and planes, such as carved sculptures. The overall design of the work-its main volume, proportions and axial arrangement-is determined by the underlying form; and smaller forms, surface shapes and decorative details are formed around and supported by this underlying structure. Secondly, because its extension to the space is not limited by the size of the material block, model sculptures are often more free and expansive in space design than sculpture sculptures. If you want to use the tensile strength of metal in the finished product, you have almost unlimited freedom; the design of brittle materials such as concrete or plaster is more restricted. Third, the plasticity of clay and wax encourages smooth and direct manipulation. Many sculptors, such as Auguste Rodin, Giacomo Manzu and Sir Jacob Epstein, like to keep it in the finished work. This direct handling of media recording. Their method contrasts sharply with the methods of Benin and Indian bronze sculptors, who improved the surface of the work to remove all traces of personal “handwriting”.

Constructing and assembling

Constructed or assembled sculptures are made by connecting pre-formed materials. In principle, it is completely different from sculpture and model sculpture, both of which are made of the same material. Man-made sculptures are made of basic prefabricated components such as metal tubes, rods, plates, rods and sheets; wooden slats, planks, dowels and blocks; laminated wood and chipboard; plexiglass, formica and glass sheets; fabrics; and wires And thread. These are cut into various sizes and can be shaped before assembly or used as is. The term “combination” usually refers to a structural sculpture that contains a large number of ready-made, so-called ready-made objects, such as old boilers, typewriters, engine parts, mirrors, chairs, table legs, and other old furniture. Many techniques are used to connect these components, of which large Part of it comes from processes other than traditional sculpture; for example, metal welding and brazing, carpentry, bolting, screwing, riveting, nails, and bonding with new strong adhesives.

The use of architectural techniques to make sculptures is the main technological development of art in recent years. One of the reasons for its popularity is that it can easily emphasize the spatial aspect of sculpture, which is what many artists in the 20th century paid attention to. It is faster than sculpting and modeling; many sculptors and critics believe that it is particularly suitable for technological civilization; it opens up new image fields and new symbolic meanings and forms.

For the “gallery” sculptures constructed, almost any material and technique can be used, and the products are often very short-lived. But architectural sculptures, outdoor sculptures, and virtually any sculpture in actual use must be constructed in a safe and at least reasonably permanent way. Therefore, the materials and technology used are limited to some extent. Metal sculptures constructed by riveting, bolting, and most importantly welding and brazing are most suitable for outdoor use.

Welding

In recent years, the introduction of oxyacetylene torches as a tool for sculptors has revolutionized metal sculptures. Around 1930, Spanish sculptor Julio González took the lead in combining welding and forging techniques; in the 1940s and 1950s, it became a major sculpture technique, especially in the United Kingdom and the United States. Its biggest representative is David Smith. In the 1960s and early 1970s, more complex electric welding processes were replacing flame welding.

Welding equipment can be used to join and cut metals. Welded joints are made by melting and fusing the surfaces of two pieces of metal together, usually adding a small amount of the same metal as a filler. The most widely used metal for welding sculptures is mild steel, but other metals can also be welded. In brazed joints, the base materials are not actually fused together, but are joined together by an alloy that melts at a lower temperature than the base materials. Brazing is particularly useful for joints between different types of metals that cannot be welded, and for connecting non-ferrous metals. Forging is the direct shaping of metal through bending, hammering and cutting.

Direct metal processing technology has opened up a whole new range of forms for sculptors-open skeleton structure, linear and highly extended forms, and complex curved sheet forms. The constructed metal sculpture may be precise and clean, like the minimalist sculptors Donald Judd and Philip King, or it may use the texture effect of molten metal in a free, “romantic” way.